On-site observation and application demonstration of pear dobby picking robot in Jurong, Jiangsu

Intelligent Equipment Empowers Efficient Orchard Harvesting and Drives Modernization of the Fruit Industry

A research institute of the Chinese Academy of Agricultural Sciences held an on-site observation meeting for the pear multi-arm picking robot in Changligang, Houbai Town, Jurong City, Jiangsu Province. It showcased China's first all-weather multi-arm collaborative "picking-harvesting-transportation" integrated orchard picking robot, demonstrating and promoting intelligent pear harvesting. The event received high praise from attending leaders, experts, and fruit growers.

Overall Appearance of Pear Multi-Arm Picking Robot (China's first all-weather multi-arm collaborative model)

Robot Picking Operation Site (Precise identification and grasping)

On-site Observation Meeting Scene (Experts and fruit growers watching the demonstration)

The picking robot was jointly developed by a research institute of the Chinese Academy of Agricultural Sciences and several high-tech companies. It is an intelligent solution developed to address the pain points of the fruit industry, such as labor shortage, high production costs, and low production efficiency.

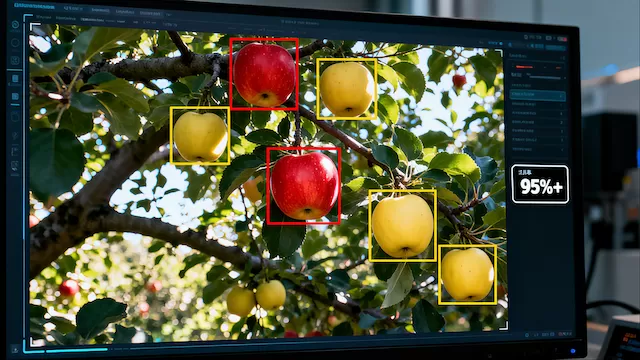

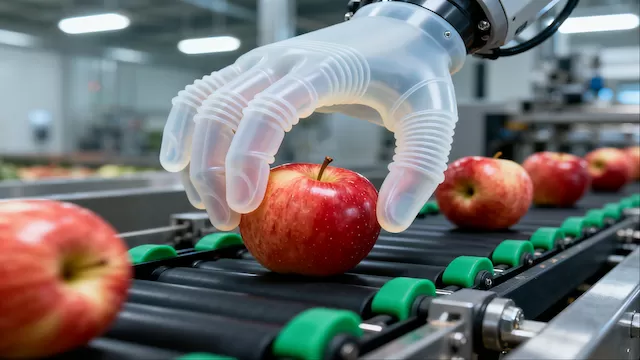

This first domestic all-weather multi-arm collaborative "picking-harvesting-transportation" integrated orchard picking robot integrates multiple advanced technologies such as machine vision, intelligent control, and precision machinery. It can realize a series of operation processes including automatic identification, precise positioning, flexible grasping, and automatic transportation of pears.

At the on-site observation meeting held in Changligang, Houbai Town, Jurong City, Jiangsu Province, the robot demonstrated on-site operations. Its stable performance and efficient picking capability were unanimously recognized by attending leaders, experts, scholars, and local fruit growers, providing strong support for the intelligent upgrading of the fruit industry.

The pear multi-arm picking robot provides a comprehensive intelligent solution for orchard harvesting through multiple innovative technologies:

Adopting waterproof and dustproof design and adaptive lighting system, it can work stably under different weather conditions, breaking through the limitation of traditional picking affected by weather.

Equipped with advanced SLAM navigation technology and multi-sensor fusion obstacle avoidance system, it can autonomously plan paths and flexibly avoid obstacles in the orchard.

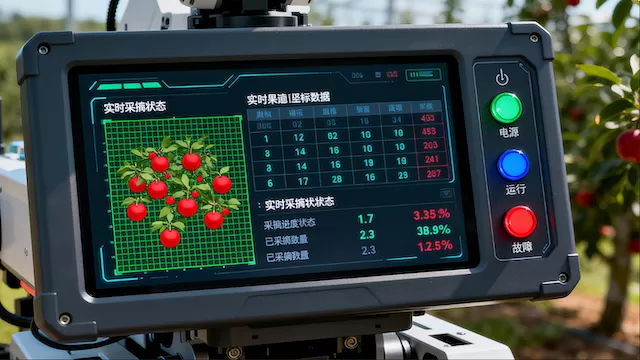

It can connect to the cloud platform, upload picking data in real-time, support remote monitoring and management, and provide data support for orchard production decisions.

Changligang, Houbai Town, Jurong City, Zhenjiang City, Jiangsu Province (an important pear industry planting base in Jiangsu Province)

The robot can complete pear picking operations in various complex environments. The picking quality and efficiency have reached or exceeded manual levels, effectively solving the problem of labor shortage in orchards.

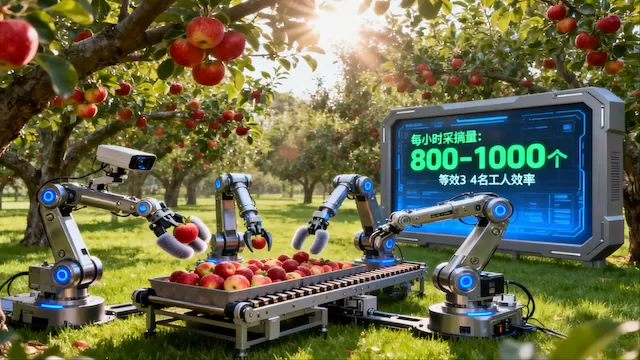

The robot demonstrated on-site can pick 800-1000 pears per hour, which is 3-4 times more efficient than manual picking, providing a feasible model for the intelligent and large-scale development of the fruit industry.

It provides a complete technical solution for the orchard harvesting process, not only reducing labor intensity and production costs but also improving the standardization level of picking, promoting the transformation and upgrading of the fruit industry.

"This pear multi-arm picking robot has reached the domestic leading level in terms of recognition accuracy and picking efficiency. In particular, the multi-arm collaborative operation technology has solved the problem of low efficiency of traditional picking robots, providing an important breakthrough for mechanized harvesting in the fruit industry."

"What we lack most is picking workers, especially during peak seasons. It's difficult to hire people and the cost is high. If this robot can be promoted, it will really solve a big problem for us fruit growers. After watching the demonstration, the picked fruits are not damaged, and it's even more careful than manual labor."

Feedback from the project R&D team: The feedback collected at this on-site observation meeting is very valuable. We will further optimize the robot's performance, reduce costs, and improve adaptability according to the suggestions of experts and fruit growers, striving to realize industrial application as soon as possible and contribute to promoting the intelligent development of China's fruit industry.

The pear multi-arm picking robot is expected to complete industrialization testing in 2026 and enter the market promotion stage in 2027. Future development will be deepened in the following aspects: first, further reduce equipment costs to make it more suitable for small and medium-sized farmers; second, expand the scope of application and develop picking robots suitable for various fruits such as apples, citrus, and peaches; third, build an integrated intelligent production line of "picking-grading-packaging" to comprehensively improve the intelligence level of the fruit industry.

With the continuous maturity of technology and cost reduction, it is expected that in the next 5-10 years, intelligent picking robots will be widely used in major fruit-producing areas in China, significantly improving industrial competitiveness and promoting the process of agricultural modernization.